![]()

Certified to International Standards: DNV 2.7-1, DNV 2.7-3, IS EN ISO 10855-2, IS EN1677-4, ASME B30.26, API-2CCU - Aug. 2017

The HA range of Grade 8 master links and quad assemblies are widely used for offshore rigging and lifting sets for containers and are the industry leaders globally based on the following:

- Product available in diameters from 22mm up to 75mm and working load limits from 7 tonnes to 100 tonnes.

- The links are manufactured from triple alloy steel in accordance with IS EN1677, which includes individually proof load tested to 2.5 times working load limit and 100% MPI.

- MPF (Manufacturing Proof Force): 2.5 x 9.81 x Working Load Limit (kN) (min.).

- MBL (Minimum Breaking Load): WLL x Factor of Safety.

- WLL (Working Load Limit) @ 45° to vertical.

- Factor of Safety: 5 : 1.

- Embossing: as per Description column and Batch Number.

- Design air temperature -40°.

- Average impact energy (charpy) 42 Joules minimum impact resisitance at -40°C up to 50mm diameter.

- Operational temperature range is -40° C to + 200°C.

- Incorporating Zinc Tough TM Technology.

- Hardness range 34 - 36 HRC.

![]()

The Zinc-ToughTM Technology HA range of Grade 8 Master Links and Quad Assemblies provide superior protection from Hydrogen embrittlement and stress corrosion cracking - making them perfect for lifting operations in offshore environments.

Hydrogen embrittlement is the process by which metals such as steel become brittle and fracture under stress due to the introduction and subsequent diffusion of hydrogen into the metal - it can also be described as hydrogen assisted stress cracking and is particularly prevalent in the extreme conditions of the offshore environment where corrosion is a consistent threat. William Hackett and McKinnon Chain combined their technical knowledge and worked alongside a wide range of stakeholders, including several major oil and gas operators, to develop Zinc ToughTM Technology.

This unique manufacturing process delivers a master link with the tensile strength requirements to deliver a 5:1 safety factor with a hardness value as low as 34-36 HRC. The DNV charpy impact values are achieved at -40C, making the links ability to withstand a shock load at any operating temperature.

DNV Type Approval TAS0000337

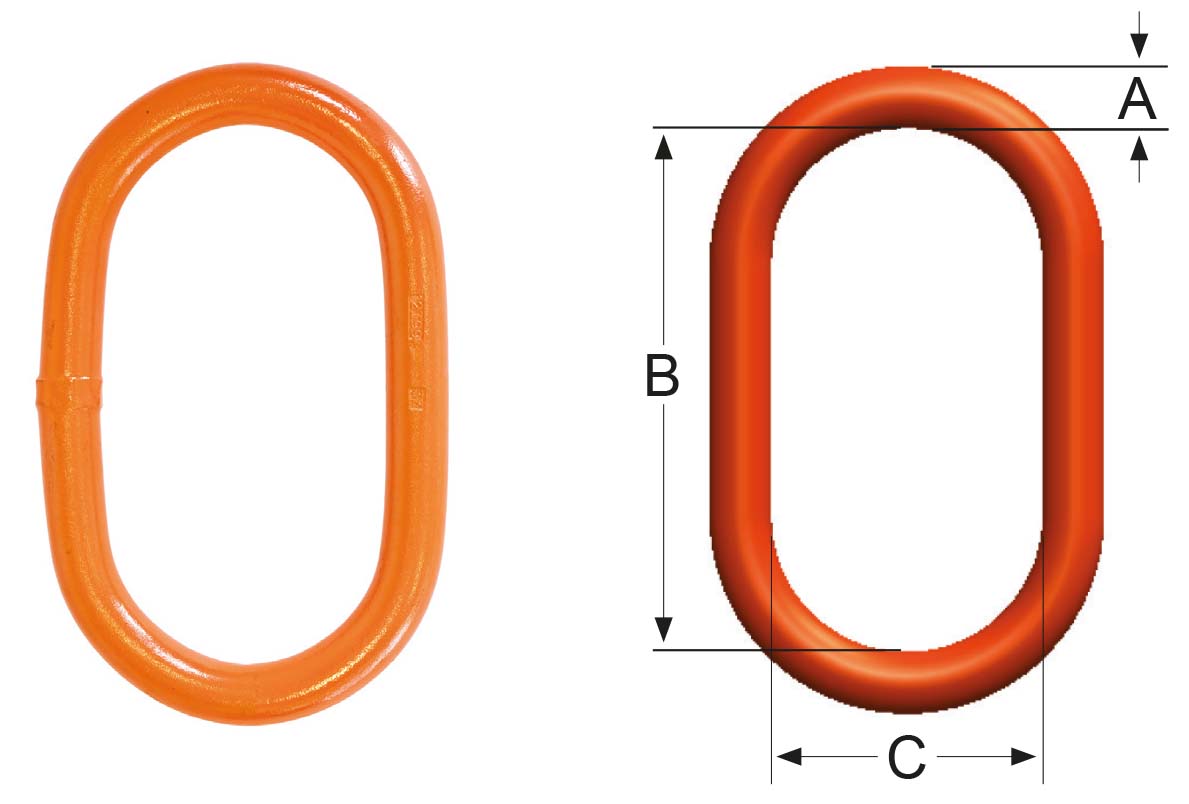

| Product Code |

Description | A mm |

B mm |

C mm |

W.L.L. (t) |

MPF kN |

MBL kN |

Mass (kg) |

|---|---|---|---|---|---|---|---|---|

| 330.220.+ZT | HA22ML OS+ ZT | 22.0 | 270 | 140 | 7.00 | 172 | 343 | 2.28 |

| 330.250.+ZT | HA25ML OS+ ZT | 25.5 | 270 | 140 | 9.30 | 229 | 456 | 3.11 |

| 330.280.+ZT | HA28ML OS+ ZT | 28.0 | 270 | 140 | 14.50 | 356 | 711 | 3.78 |

| 330.320.+ZT | HA32ML OS+ ZT | 32.0 | 270 | 140 | 19.00 | 466 | 932 | 5.02 |

| 330.360.+ZT | HA36ML OS+ ZT | 36.0 | 270 | 140 | 26.00 | 638 | 1275 | 6.46 |

| 330.400.+ZT | HA40ML OS+ ZT | 40.0 | 280 | 155 | 30.50 | 749 | 1496 | 8.46 |

| 330.450.+ZT | HA45ML OS+ ZT | 45.0 | 320 | 175 | 40.00 | 981 | 1962 | 12.18 |

| 330.500.+ZT | HA50ML OS+ ZT | 50.0 | 350 | 195 | 51.00 | 1251 | 2502 | 16.54 |

| 330.650.+ZT | HA65ML OS+ ZT | 65.0 | 410 | 220 | 75.00 | 1840 | 3679 | 33.02 |

| 330.750.+ZT | HA75ML OS+ ZT | 75.0 | 450 | 250 | 100.00 | 2453 | 4905 | 48.98 |

Swipe horizontally on Specs Table to view all information.